1) The kind of screed used for the installation of parquet flooring should be smoothed bright screed which is made by using eight bags of 400 grade cement mixed with fresh water sand (preferably river sand) and applied with a steel trowel. Salt water sand (sea-sand) holds salt for extensive periods of time. That negatively affects dry parquet. The use of sea sand is thus not recommended. Cement dust should not be sprinkled during smoothing because it may cause swelling of the screed.

2) As Abant Parke parquet products are exported, they conform to world humidity level standards (8-10%). As for the longevity of your parquet flooring, it is necessary that the screed has to dry well. For that to happen, the screed should be allowed to dry for two months between the months of April and the end of October. The same length of time may be valid during other months, provided central heating is on. If central heating is not on, installation process may start after May.

3) The surface must be thoroughly cleaned before the installation process. There should be no lime or mortar residue on the surface. If there remains mortar applied for any purpose on the screed, until the moisture that is caused by that process dries (approximately one month), installation of the parquet must not be started.

4) The installation of parquet is done by using the double-component polyurethane glue provided or recommended by our company and with the glue comb sent by our company on the screed described above. For solid wood planks, the moisture and concrete primer is applied, using a roller or a brush. One day after the application, using double component polyurethane glue, the parquet is adhered to the floor.

5) If the screed is not as described above, and the wooden trowel is not smooth and has roughness, the special glue is mixed with screed powder, and a viscous paste is thus obtained and laid on the concrete floor. By using a gauge rake, a thin layer is formed. 2-3 days after that, glue is applied on the hardened layer with a comb and afterwards installation of the parquet starts. If desired, dipping can be applied on top of it. Dipping ensures adhesion but never functions as insulation.

6) When installation is being done, the installed massive parquets are moistened at every 0,5 m2 or the most 1 m2 with a wet big sponge or cloth. Since parquet is very dry (6 - 8%), this moistening will create room for the parquet to settle and swelling will thus be avoided. For beech, sapele and rose, the moisturizing process is done by moistening the material more than the other tree types.

7) To prevent swelling of parquet and its pressuring the walls, do the wall corner miter cuts at least one week after the entire floor installation is finished and start with the part where installation started and install the baseboards.

8) Prior to the installation of massive parquet, window installation, wall paper installation, heating and plumbing installation and trials must absolutely be done. After parquet installation is finished, spread wood chips on the parquet and wait for at least 10 days.

9) After sanding the parquet, mix the finest silica powder with the filler until you obtain a viscous paste. Do priming, using the paste. After the paste hardens, sand it with sandpaper and apply the first coat of parquet varnish.

10) Even after the final coat of polish dries, do not walk on the parquet with shoes or dusty, dirty feet for at least one week.

11) The windows in uninhabited storeys should especially be opened in the morning and closed at night and the parquet must absolutely be ventilated.

12) Everything mentioned above applies to the installation of solid wood planks. Installation is done in two different ways;

A) By applying moisture and concrete primer, solid wood planks are glued directly to the screed, using polyurethane double component glue.

B) Installation starts by installing 2.5x5 cm dried pine timbers, which have the same thickness and size, in the reverse direction of the flooring at intervals of 30 cm. Styrofoam is placed for sound insulation among timbers. For sound insulation, the styrofoam must be installed to be 1 mm higher than the timbers. As this process requires elevation lime powder is laid underneath. Lime powder also prevents any possible woodworm infestation. After that, massive parquet is installed on the timbers by fastening tenons through mortises with sprigs and glued together.

13) No kind of parquet may be installed on marble, ceramic and vinyl flooring. Laminate parquets may be installed using floating system installation by laying polystyrene foam flooring plates (cords) underneath them. About 1.5 months after full drying, the floors may be removed, the screed is repaired and parquet installation may commence. It is necessary to remove vinyl flooring in the same way, and clean and remove the bitumen on the screed very well.

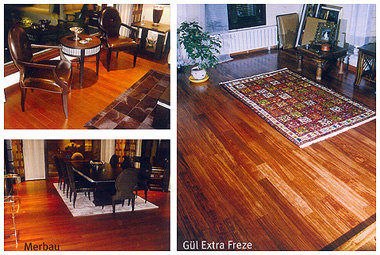

1) Our laminated parquet products are extremely different from the laminate flooring products in the market. Our laminated flooring products are made of natural wood only. In ordinary laminate flooring products, on the other hand, the patterns on the upper surfaces are photos of the wood and are produced by PVC coating on the wood pattern paper.

2) Abant Parke brand Forest Flooring laminate parquet is covered with natural wood on both sides. As its bottom surface is covered with protective lacquer, it is resistant to moisture which may come from the bottom surface.

3) The top surface of our Forest Flooring laminated parquet flooring is made of natural wood and is produced by using the German Kleibert Hot Coating system, using 44 gr/m2 weight in the production of our residential parquets, which is recommended by the company for workplaces and hotels. (With this application, the resistance our products to impacts and scratches have been highly increased). The average life of this product in houses is approximately 35 years.

4) Forest Flooring laminate parquet flooring products are 11-13 mm thick. Therefore, they are 4mm thicker than the laminate floorings commonly found in the market. Because the bottom and top surfaces of our products are natural wood, they are flexible and because they establish full contact with the floor and because natural wood absorbs sound, our products are 5 times quieter than other laminate flooring products in the comparative measurements made.

5) Since the top surface is natural wood and the 44 gr/m2 special hot coating system is applied as a textured varnish, our product absorbs heat and keeps the environment warm long after the central heating is turned off. You can feel this difference and the warmth even when you step on it on bare foot. The heat absorption of our products on the surface also provides a significant energy savings. Our company has a patent in this regard.

6) Since Hot Coating has special water-repellent properties, it does not absorb water even in partial flooding, and it is not warped and deformed.

7) The German Kleibert brand Hot Coating system lacquer is much more durable and flexible than all other lacquer systems. Particularly, it is not affected by stiletto heels. The average life of the lacquer in homes is about 40 years.

8) Interlocking system used in our products allows the possibility of replacing only the damaged parts on the parquet floor when it is damaged. Interlocking system saves you the sanding and polishing of the entire surface, loss of time, dirt and residue, and breathing dust and lacquer smell. It also saves you substantial money. To give an example, as of 2018 sanding and polishing a 40 m2 living room costs between 1500-2000 TL. In addition, you have to remove everything in the room completely. In the interlocking system, this cost is maximum 80-100 TL. Besides, you do not need to remove everything in the room either.

9) For cleaning: Mix a little bit of liquid soap (a pinch or a spoonful) in half a bucket of warm water. Soak the mop in the water when it becomes white with the soap and wring it thoroughly. The floor is wiped this way and is dried off with a dry mop. You will see that this application vitalizes the lacquer.